02-09

RF RACER Brand Leverages Motorsport Heritage for Engineering Excellence

2026-01-23

2026-01-23

On August 26, 2025, the China Association of Automobile Manufacturers officially released the group standard T/CAAMTB 286—2025, titled "Road Test Methods and Evaluation of Brake Noise and Judder for Passenger Vehicles." Among the drafting members—including major industry players such as FAW-Volkswagen, Geely Research Institute, Zeekr, Xiaomi Auto, Chery, Great Wall Motor, XPeng Motor, and Bosch—a private company named Chengdu Jishiwei (JSW) Automotive Technology Co., Ltd. stood out.

(Wang Xiong — Active Competition in the China Rally Championship (CRC)

(CAAM Association Group Standards Listing Showing JSW as a Drafting Unit)

From a single national racing license in 1999 to contributing to the formulation of a national-level brake industry standard in 2025, JSW founder Wang Xiong has completed a 26-year journey. It is a transformation from mastering machines on the track to defining the machines themselves—a full-circle evolution from racer to rule-maker.

FIA-Authorized National Racing Licence (1999)

Continuous Motorsport Validation: From Racing Experience to RF Brake Engineering

Throughout the 2000s, RF RACER accumulated extensive motorsport data through rally events, endurance races, and off-road competitions. These years of continuous motorsport validation directly informed the evolution of RF Brake systems, addressing industry-wide challenges such as brake fade, thermal instability, uneven pad wear, and loss of pedal consistency.

Rather than pursuing visual differentiation or short-term performance gains, RF RACER focused on structural optimization, thermal management, and mechanical reliability. Each generation of RF Brake components was refined through repeated competition cycles, ensuring that solutions developed for racing environments could reliably outperform standard braking systems in civilian use.

(Competing in national-level rally events since the late 2000s)

This period laid the technical foundation for RF RACER’s future innovations, establishing RF Brake not merely as a product line, but as a motorsport-derived braking engineering framework.

Patent Strategy and Industrial Transformation: Building RF Brake as a Technology Platform

As RF RACER entered a more mature development stage, the company began systematically formalizing its engineering achievements through a structured patent strategy and long-term intellectual property framework. A series of proprietary technologies related to caliper structures, heat dissipation paths, floating interfaces, and system integration were secured under RF RACER’s patent portfolio, reinforcing RF Brake as a protected engineering platform.

(Certified manufacturing backed by established quality management systems)

In parallel, RF RACER completed a comprehensive industrial transformation, aligning its manufacturing and quality management systems with ISO 9001 standards. This milestone marked a critical transition from motorsport-driven experimentation to scalable, globally compliant production. Every RF Brake system leaving the factory follows standardized engineering verification, traceability, and quality control protocols, ensuring consistency without compromising performance integrity.

Engineering Milestone: Structural Innovation in Carbon-Ceramic Braking

RF RACER completed patent-driven optimization across caliper structure and mounting systems, including new designs for caliper geometry, roof-mounted functional brackets, and a breakthrough heat management structure for brake calipers. These advancements improved the reliability and adaptability of high-performance braking systems. Notably, the RF RACER team successfully completed the development of a floating connector for carbon-ceramic brake discs and obtained patent authorization, reinforcing system-level stability and assembly consistency under mass-production conditions.

Strategic Collaboration & Industrial Validation

In 2025, RF RACER and STOPART jointly presented their collaborative achievements at both GT SHOW and AIT, China’s leading automotive performance exhibitions. The joint showcase demonstrated phased results in carbon-ceramic system engineering and highlighted the growing synergy between the two companies in high-performance braking technologies.

Simultaneously, STOPART achieved a major OEM breakthrough. Its carbon-ceramic brake components have passed full-vehicle validation testing by several global automakers and have entered serialized production and delivery. This milestone confirms STOPART’s capability to meet OEM requirements for quality assurance, consistency, and scalable manufacturing. The mature technical partnership—coupled with STOPART’s proven production capacity—establishes a strong, replicable industrial foundation for the continued evolution of RF Brake’s carbon-ceramic systems across both motorsport-derived and production-oriented applications.

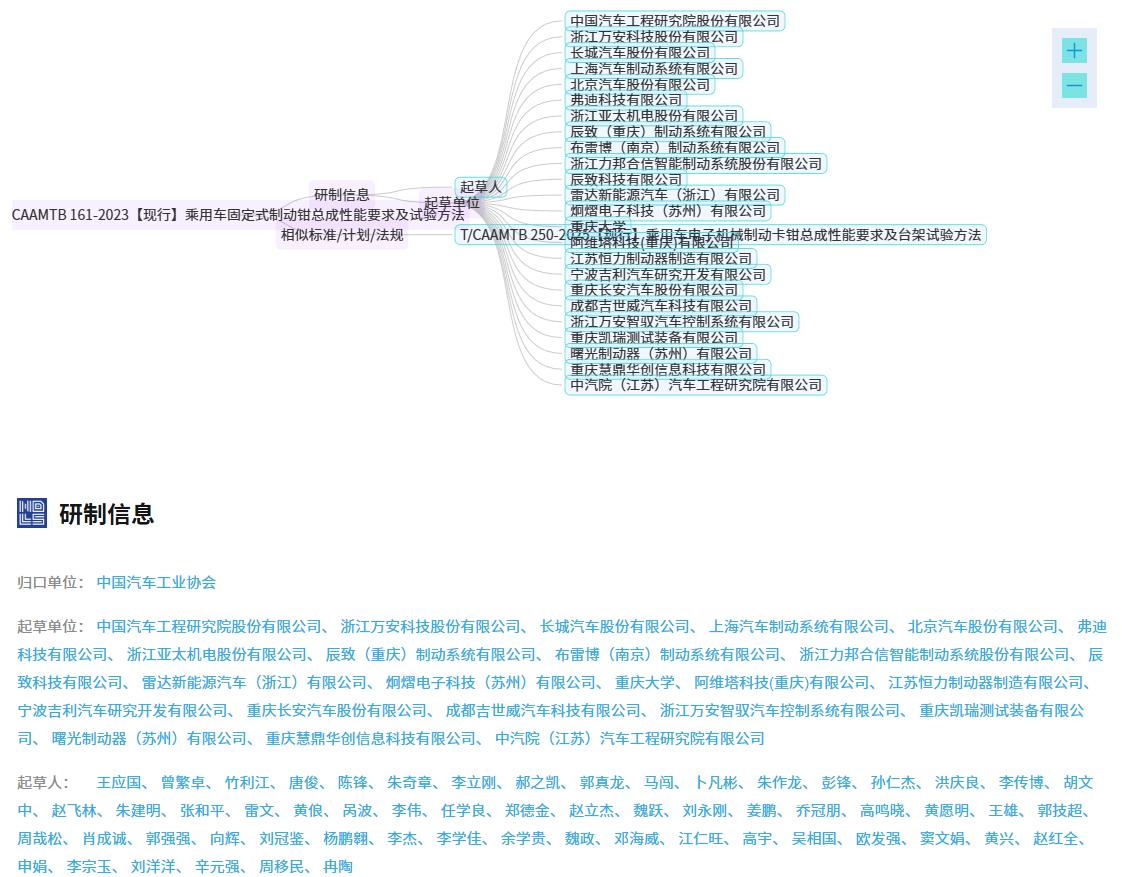

Asserting Industry Authority: JSW's Early Role in Standardization

As early as December 2023, JSW had already demonstrated authoritative influence in the brake system segment. In the group standard T/CAAMTB 161-2023, titled "Performance Requirements and Test Methods for Fixed-Type Brake Caliper Assemblies for Passenger Vehicles," issued by the China Association of Automobile Manufacturers, JSW was one of the core drafting entities. This standard filled a longstanding industry gap and established strict testing protocols for high-performance fixed opposed-piston calipers. Its publication marked JSW's transition from pure manufacturing toward high-end precision and intelligent manufacturing.

(Standard Drafting Structure for CAAMTB Automotive Braking Regulations)

JSW Braking System Laboratory: Engineering Validation at System Level

To further strengthen its technical independence, JSW established the JSW Braking System Laboratory, which provides dedicated validation support for RF Brake engineering under the RF RACER brand. The laboratory integrates bench testing, thermal simulation, fatigue testing, and system-level verification, enabling engineers to reproduce extreme operating conditions within a controlled environment.

Every RF Brake system undergoes comprehensive validation before entering production, ensuring compatibility across calipers, discs, pads, and hydraulic interfaces. The laboratory supports continuous iteration and optimization, reinforcing RF RACER’s commitment to engineering credibility through data-driven validation rather than marketing claims.

Expanding Applications: RF Brake Systems for Modern Performance Demands

In recent years, RF RACER has expanded the application scope of RF Brake systems to address emerging automotive trends. High-performance braking solutions have been developed for electric vehicles, where increased vehicle weight and instantaneous torque place greater demands on braking stability and thermal capacity.

At the same time, building on its passenger vehicle foundation, RF RACER continues to refine RF Brake solutions for off-road and SUV platforms, focusing on improved durability, environmental resilience, and stable braking control under prolonged load conditions.

Conclusion: Motorsport Heritage as the Core of RF Brake Engineering

From its founding in 1999 to its current role as a technology-driven braking brand, RF RACER has consistently demonstrated how motorsport heritage can be transformed into engineering excellence. Every major milestone—years of motorsport validation, structured patent development, ISO 9001 industrial transformation, the JSW Braking System Laboratory, and OEM-certified floating connector technology for carbon-ceramic discs—together contributing to the exceptional quality of the RF Brake platform.

(An established manufacturing and engineering base supporting long-term operations)

RF Brake is not a marketing label, but a system-level braking philosophy developed by RF RACER through decades of real-world validation. As automotive performance standards continue to evolve, RF RACER remains committed to advancing RF Brake engineering, ensuring that motorsport-derived braking technology delivers confidence, safety, and control in the most demanding environments.

คำปฏิเสธ: บทความนี้ทำซ้ำจากสื่ออื่น ๆ วัตถุประสงค์ของการพิมพ์ซ้ำคือการถ่ายทอดข้อมูลเพิ่มเติมไม่ได้หมายความว่าเว็บไซต์นี้เห็นด้วยกับมุมมองและรับผิดชอบต่อความถูกต้องและไม่รับผิดชอบใด ๆ ตามกฎหมาย แหล่งข้อมูลทั้งหมดในเว็บไซต์นี้ได้รับการรวบรวมบนอินเทอร์เน็ตจุดประสงค์ของการแบ่งปันคือเพื่อการเรียนรู้และการอ้างอิงของทุกคนเท่านั้นหากมีการละเมิดลิขสิทธิ์หรือทรัพย์สินทางปัญญาโปรดส่งข้อความถึงเรา